-

-

-

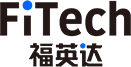

Ultra-Fine Solder PasteUltra-Fine Epoxy Solder PasteAnisotropic Conductive PasteGold-Tin Solder PasteSolder Paste for Multiple Reflow SolderingWater Soluble Solder PasteHigh-Temperature Solder PasteLow-Temperature Solder PastesHigh Reliability Solder PasteLaser Solder PasteLead-Free Silver-Free Solder PasteLow Alpha Solder Paste

-

-

-

-