Detailed explanation of the causes of non-wetting open soldering and improvement measures

Detailed analysis of Non Wet Open (NWO) and suggestions for improvement

I.the definition and typical characteristics

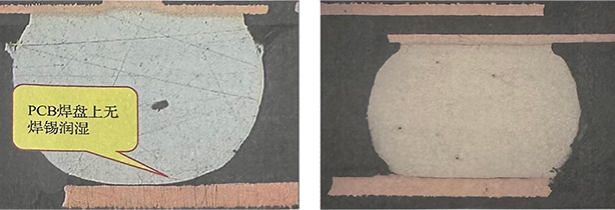

Non

Wet Open (NWO) refers to the PCB (Printed Circuit Board), BGA (Ball

Grid Array) pads do not achieve a good wet open solder joints.Typical

characteristics of its slicing diagram for all or part of the PCB pads

on the lack of solder wetting, as shown in Figure 1-1 (not attached

here, but a clear description).

图 1-1 无润湿开焊焊点切片图

II. Causes

BGA warpage causes solder paste to pull up

Formation

stage: No wetting open solder joints usually begin to form in the

temperature rise stage of reflow soldering (160 ~ 190 ℃).

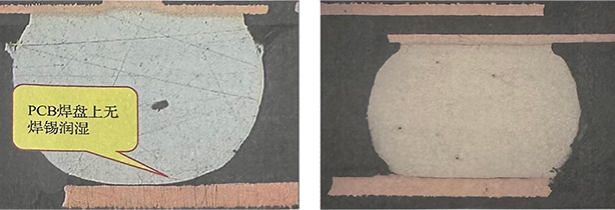

Formation

mechanism: As shown in Figure 1-2, BGA warpage occurs, the solder paste

will be brought to the BGA solder ball, due to the separation of the

solder paste and pads, resulting in the formation of good solder joints.

Figure 1-2 Mechanism of non-wetted open solder joint formation

Other conditions that lead to open solder joints

Solder Paste Leakage: Solder paste is not properly printed onto the pads.

Oxidation of solder pads: Oxidation on the surface of the pads affects the wettability of the solder.

Dirt

on the pad or flux process problems: Dirt on the pad surface or

improper use of flux, resulting in the solder not being able to wet

well.

Root cause

The

root cause of this defect is the deformation of the BGA and the pulling

up of the solder paste.Huawei's Zhu Ailan et al. conducted an in-depth

study on the causes of solder paste pull-up, and found that there is no

direct correlation between the phenomenon of solder paste pull-up and

its low-temperature activity, high-temperature adhesion and adhesion

stability.However, through the low temperature over the furnace (below

the melting point of the solder paste) direct pull-up method to study

the solder paste pull-up phenomenon, the results show that the

probability of the solder paste is pulled up for 0~7.6%, at least show

that this phenomenon exists.Warpage and the probability of NWO failure

can be significantly reduced by lowering the reflow temperature.

III. the identification method

Non-wetting

open soldering can be identified by X-Ray.As the solder paste is

covered with solder balls, the solder joints are usually significantly

larger than the surrounding solder joints.If this phenomenon corresponds

to the failed solder joints, it is basically confirmed that there is no

wetting open soldering phenomenon.

Suggestions for improvement

For

non-wetting open soldering phenomenon, need to analyse specific cases,

but generally should follow the following recommendations for

improvement:

PCB on the surface before cleaning

Ensure

that the PCB on the line before a thorough surface cleaning to remove

the pad surface of the oxide layer, dirt, etc., to improve the

wettability of the solder.

Use SPI to monitor solder paste printing quality

SPI

(Solder Paste Printing Inspection) is used to monitor the quality of

solder paste printing to prevent leakage of printed veneers from flowing

into subsequent processes.The SPI allows real-time detection of the

amount of solder paste printed, the printing position and other

parameters to ensure that the quality of solder paste printing meets the

requirements.

Other Improvement Measures

Optimise

soldering process parameters: according to the characteristics of PCB

and BGA, optimise the temperature profile, time and other parameters of

reflow soldering to ensure that the solder can fully wet the pad.

Enhance

the fixing of BGA: Increase the fixing measures of BGA on PCB, such as

the use of glue, bracket, etc., to reduce the warping and deformation of

BGA in the welding process.

Regular

inspection and maintenance of equipment: Regular inspection and

maintenance of soldering equipment to ensure the accuracy and stability

of the equipment to reduce soldering defects caused by equipment

problems.